Products

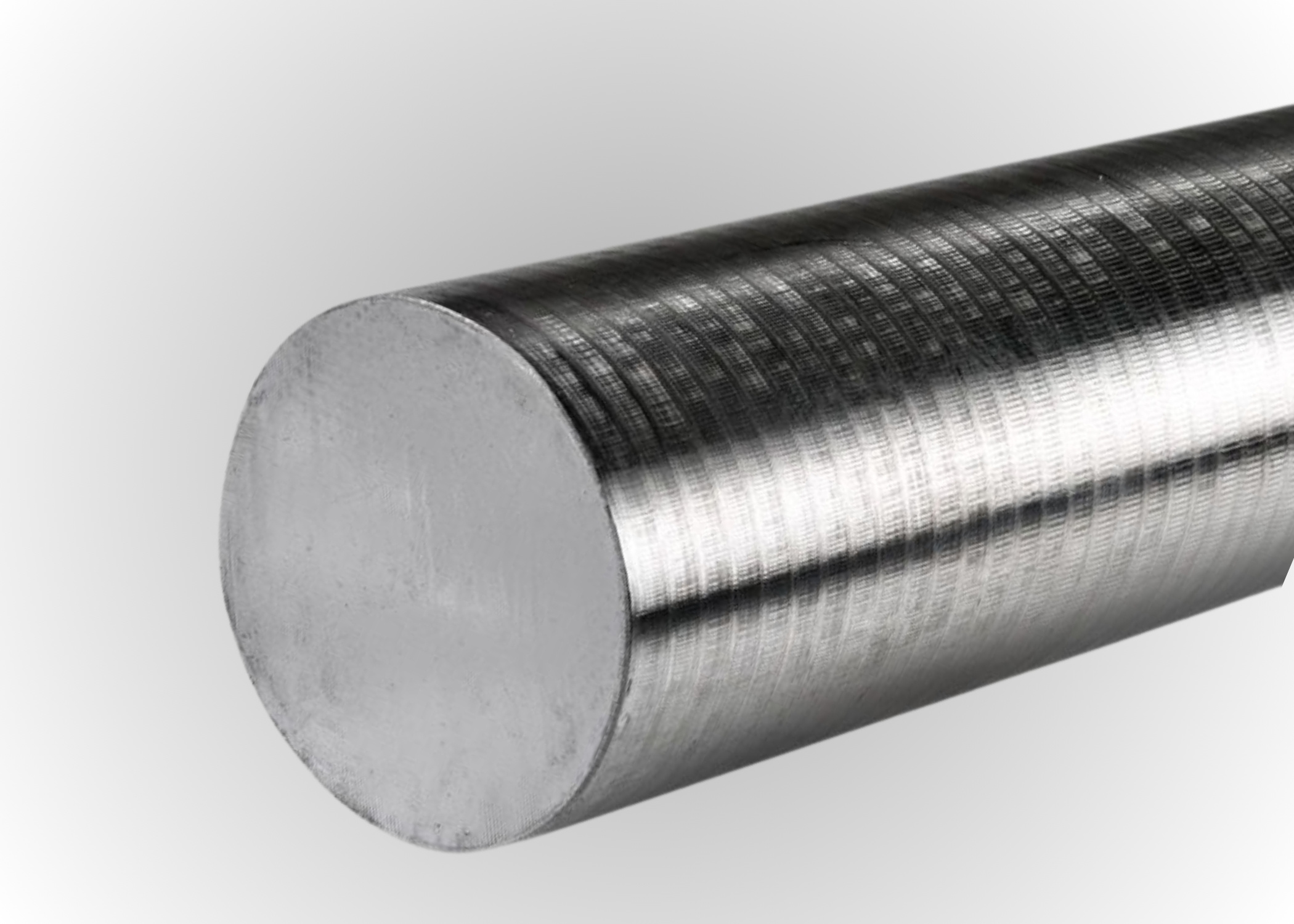

Cold Drawn Bars

Crafted for Strength, Drawn for Precision

Bright bars are a key product offered by K.R. Steel Udyog, known for their superior quality and precise dimensions. These bars are produced from black bars through a series of cold finishing processes, including drawing, peeling, grinding, polishing, and cold rolling. Our bright bars are perfect for applications requiring specific tolerances and smooth finishes, such as CNC machining.

SKU:

N/A

Category: Primary Categories

- Raw Material Procurement:

- We source round bars from top main producers like RINL, Bhushan, JSPL and other primary main producers, ensuring the highest quality raw materials for our bright bars.

- Cold Drawing:

- The bright steel round bars are drawn through dies to achieve the required shape. This process enhances yield strength and tensile strength while eliminating surface imperfections from the rolling process.

- Peeling:

- Black bars are turned to desired sizes in a peeling machine, which removes all surface imperfections and exposes any internal flaws. This process does not affect the tensile strength but ensures a smooth surface.

- Grinding:

- The grinding process is employed to narrow tolerances and improve surface finishes, ensuring the bars meet precise dimensional requirements.

- Polishing:

- Polishing further enhances the surface finish of the bars, making them ideal for applications where appearance and smoothness are critical.

- Cold Rolling:

- Cold rolling is used to produce complex shapes with precise dimensions and excellent surface quality.

- CNC Machining

- Automotive Components

- Construction Equipment

- Industrial Fasteners

- Shafts and Spindles

- Machine Tools

- Precision Engineering

- High Precision: Tight dimensional tolerances and excellent surface finishes.

- Enhanced Strength: Improved yield and tensile strength due to cold drawing.

- Surface Quality: Smooth and defect-free surfaces, ideal for critical applications.

- Versatility: Suitable for various shapes and complex profiles.

- Durability: High resistance to wear and tear, ensuring long-lasting performance.